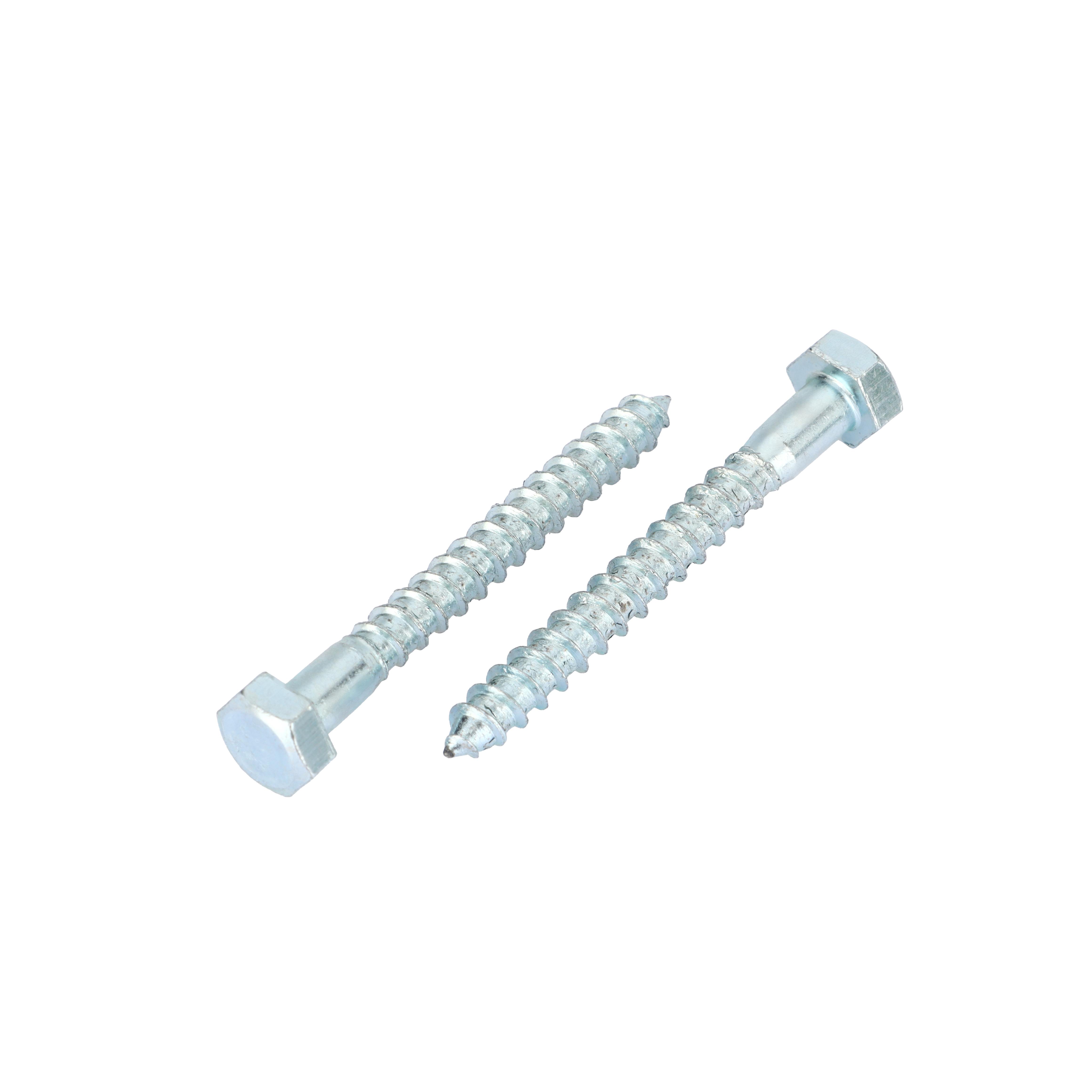

In the demanding world of construction and engineering, hexagon bolts emerge as essential fastening components that play a crucial role in ensuring the stability, strength, and integrity of structures. These bolts, characterized by their six - sided heads, offer a unique combination of functionality, durability, and ease of use, making them a preferred choice across a wide range of applications. Hexagon bolts are meticulously crafted from high - quality materials such as carbon steel, alloy steel, and stainless steel, each selected for its specific properties to meet diverse project requirements. Carbon steel hexagon bolts provide excellent tensile strength, enabling them to bear heavy loads and are commonly used in general construction projects, from joining wooden beams in residential buildings to securing metal components in industrial facilities. Alloy steel hexagon bolts, on the other hand, offer enhanced strength and resistance to wear and tear, making them suitable for more demanding applications where higher performance is needed, like in bridge construction or heavy machinery assembly. Stainless steel hexagon bolts are highly valued for their exceptional corrosion resistance, making them ideal for outdoor projects, marine applications, or environments with high humidity, as they can withstand the elements over time without rusting or deteriorating, thus maintaining the strength of the connections they create.

The design of hexagon bolts is optimized for efficient installation and reliable performance. The six - sided head allows for a better grip when using wrenches or sockets, enabling construction workers to apply higher torque levels compared to other bolt head types. This feature ensures that the bolts can be tightened securely, creating strong and stable joints that can withstand vibrations, stress, and heavy loads. Additionally, hexagon bolts come in various sizes, ranging from small diameters used for delicate assembly work to large, heavy - duty bolts capable of connecting massive structural elements. The thread patterns on hexagon bolts are also carefully engineered; coarse threads are often used for quick assembly and applications where a large amount of force needs to be transferred, such as in wooden structures, while fine threads provide a more precise and secure fit, making them suitable for applications in metalworking or where vibration resistance is crucial.

In industrial settings, hexagon bolts are integral to the assembly of machinery and equipment. They ensure that different parts are held together firmly, preventing any movement or displacement that could lead to mechanical failures. In the automotive industry, for example, hexagon bolts are used to secure engine components, suspension parts, and body panels, contributing to the overall safety and performance of vehicles. In the aerospace sector, where precision and reliability are of utmost importance, high - grade hexagon bolts are employed to assemble aircraft frames and critical systems, ensuring that the planes can withstand the rigors of flight.

The quality control of hexagon bolts is a critical aspect in their manufacturing process. Reputable manufacturers, like Jiaxing Xinhongda Technology Co., Ltd., implement strict quality standards to ensure that each bolt meets or exceeds industry specifications. This involves rigorous testing for tensile strength, shear strength, and thread quality to guarantee that the bolts can perform reliably under various conditions. Bolts are also inspected for dimensional accuracy to ensure proper fitment in corresponding nuts and holes, preventing issues such as loose connections or difficulty in assembly. Surface treatments, such as galvanization or coating, are often applied to hexagon bolts to enhance their corrosion resistance and extend their lifespan, especially for bolts used in harsh environments.

The availability and accessibility of hexagon bolts have been greatly enhanced in the modern era. With the growth of online marketplaces and a well - established global supply chain, contractors, engineers, and DIY enthusiasts can easily source hexagon bolts in the quantities and specifications they need. Online platforms offer detailed product information, including material composition, size charts, load - bearing capacities, and customer reviews, enabling buyers to make informed decisions. Many suppliers also provide bulk purchasing options, discounts, and fast shipping services, making it convenient and cost - effective to obtain hexagon bolts for projects of all scales. Whether it’s a small repair job, a large - scale construction project, or an industrial assembly task, the right hexagon bolts are readily available to meet the specific requirements of each application.

In conclusion, hexagon bolts are indispensable in construction, engineering, and various industrial fields. Their robust design, diverse material options, reliable performance, stringent quality control, and wide availability make them a cornerstone for creating secure and long - lasting connections. By choosing high - quality hexagon bolts from trusted manufacturers, professionals can ensure the success and durability of their projects, whether it’s building a sturdy structure, assembling complex machinery, or maintaining critical infrastructure.