119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

DIN 7504N Self-drilling tapping screws are usually classified as self tapping screws and self tapping teeth. The tail of self drilling screws is different from that of ordinary screws. It is not a sharp tail, but like a drill bit. This tail can drill holes by itself.

Material: Carbon Steel, 410 Stainless Steel, 304 Stainless Steel

Head Type: Pan Head

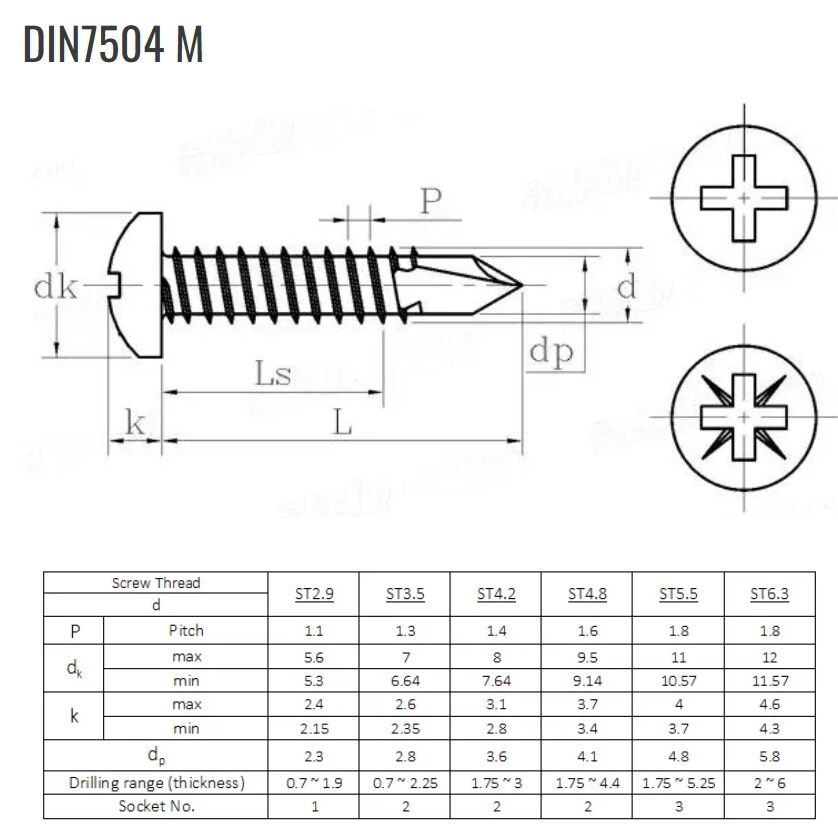

Size: ST2.9, ST3.5, ST4.2, ST4.8, ST5.5, ST6.3 Length: 10 ~180mm

Surface Finish: Zinc Plated, Yellow Plated

Drill Point: #2, #3, #4, #5

Introduce:

DIN 7504N Self-drilling tapping screws are usually classified as self tapping screws and self tapping teeth. The tail of self drilling screws is different from that of ordinary screws. It is not a sharp tail, but like a drill bit. This tail can drill holes by itself.

Material: Carbon Steel, 410 Stainless Steel, 304 Stainless Steel

Head Type: Pan Head

Size: ST2.9, ST3.5, ST4.2, ST4.8, ST5.5, ST6.3 Length: 10 ~180mm

Surface Finish: Zinc Plated, Yellow Plated

Drill Point: #2, #3, #4, #5

Details:

DIN 7504N Self-drilling tapping screws

The tail of the drilling tail screw is in the shape of drill tail or sharp tail, without auxiliary processing, it can directly drill, tap and lock on the setting materials and basic materials, thus greatly saving the construction time. Compared with ordinary screw, it has high tenacity and maintenance force, long time after combination and no loosening. It is easy to use safe drilling and tapping once.

Purpose: it is a kind of screw, which is mainly used to fix the colored steel tile of steel structure, and also can be used to fix the sheet material of simple building. It cannot be used for metal to metal bonding.

Material and model

There are two kinds of materials: Iron and stainless steel, among which stainless steel is divided into many kinds of materials.

The models are: Φ 4.2 / Φ 4.8 / Φ 5.5 / Φ 6.3mm, and the specific length can be determined according to the requirements.

According to the different drilling tails, they can be divided into:

Round head rice / Cross / plum blossom, countersunk head (flat head) / rice / Cross / plum blossom, hexagonal flower head, round head flower head (big flat head), trumpet head, etc

Mechanical performance requirements

Drill tail screw

1. Core hardness: Standard: hrc32-40

2. Surface hardness: Standard: hv600-700

3. Cemented layer: 4 × 10-6 × 10:0.05-0.18mm 8-12:0.10-0.23mm 14:0.15-0.28mm

Application