In the intricate tapestry of the construction industry, construction screws stand as indispensable workhorses, silently yet powerfully holding structures together and ensuring their stability, durability, and functionality. These unassuming yet crucial components are the backbone of countless building projects, from humble residential abodes to towering skyscrapers and sprawling industrial complexes. Construction screws come in an extensive range of types, each meticulously engineered to cater to specific construction needs and materials. Wood construction screws, for example, are designed with sharp tips and precisely crafted threads that effortlessly penetrate wooden surfaces, gripping the grain tightly to create robust, long - lasting connections. Whether it’s framing a house, building wooden decks, or installing interior wooden fixtures, these screws provide the reliability needed to withstand the test of time and the stresses of daily use.

Self - drilling construction screws take convenience and efficiency to the next level. As the name suggests, they are equipped with specialized tips that can bore through materials like metal, plastic, and even some composite materials, eliminating the need for pre - drilling holes. This not only saves valuable time during construction but also reduces the risk of errors and damage to the materials. In metal framing applications, self - drilling screws quickly and securely fasten metal studs and tracks, providing the structural integrity required for walls and other components. They are also widely used in the installation of drywall, where their ability to penetrate the gypsum board and anchor it firmly to the framework ensures a smooth and stable finish.

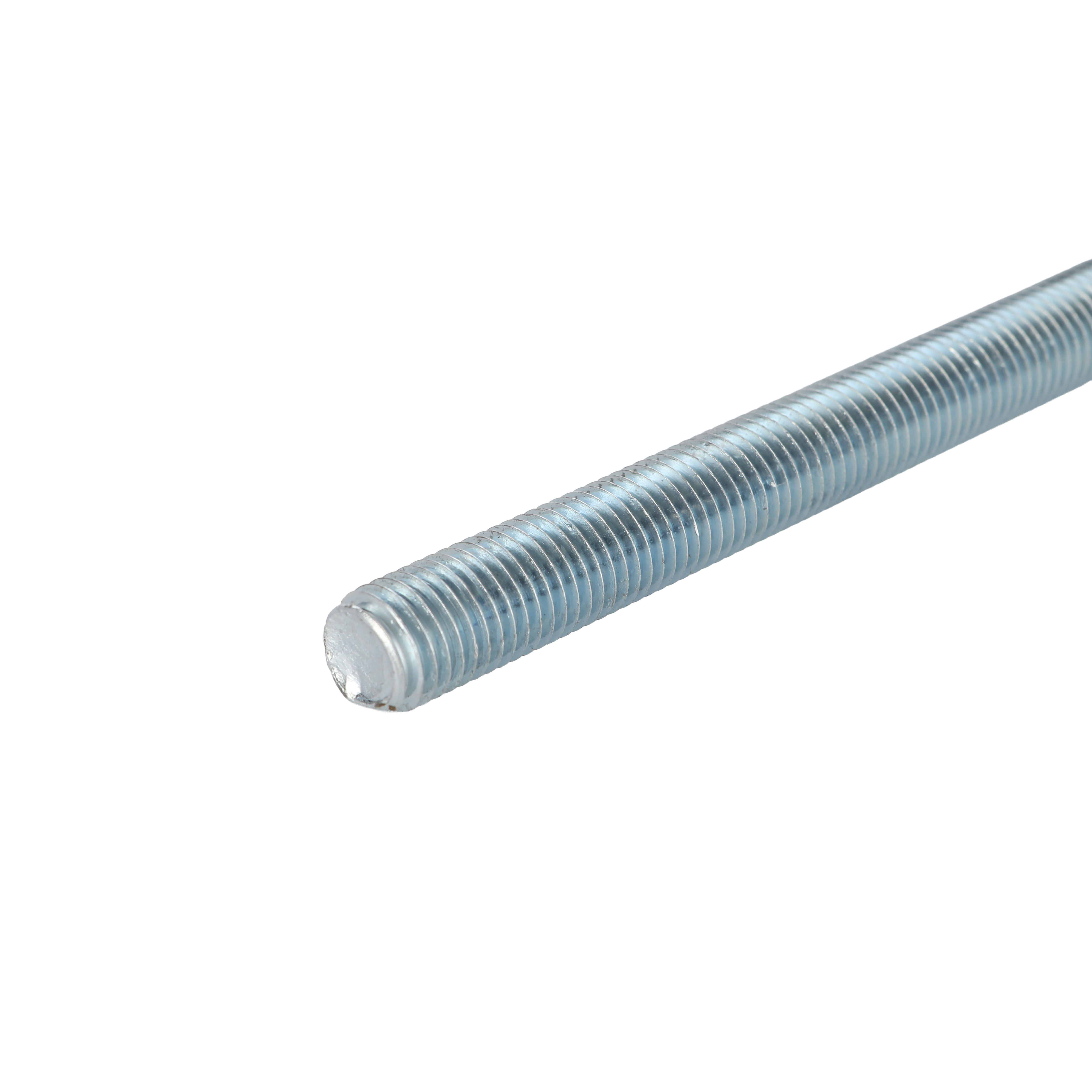

The choice of materials for construction screws is a critical factor that significantly impacts their performance and lifespan. Stainless steel construction screws are highly prized for their exceptional corrosion resistance, making them ideal for outdoor projects or environments with high humidity, such as bathrooms, kitchens, and coastal buildings. They can endure exposure to moisture, salt, and other corrosive elements without rusting or deteriorating, thereby maintaining the strength of the connections they create. Galvanized steel screws, coated with a protective layer of zinc, offer a cost - effective alternative with good corrosion protection, suitable for general construction tasks where moderate exposure to the elements is expected. On the other hand, carbon steel construction screws provide high tensile strength, enabling them to bear heavy loads and are often chosen for heavy - duty construction applications where maximum strength is required.

The design features of construction screws further enhance their functionality and usability. Different head styles, including Phillips, flat, hex, and pan heads, serve distinct purposes. Phillips - head screws are convenient for general - purpose applications as they can be driven easily with standard screwdrivers, although they may be prone to slipping under high torque. Flat - head screws are favored when a flush finish is desired, as they can be countersunk into the material surface, creating a smooth and seamless appearance. Hex - head screws, with their six - sided shape, allow for better torque application, enabling construction workers to apply higher tightening forces for more secure connections, especially in critical structural joints. Pan - head screws, with their rounded tops, are often used in applications where a more aesthetically pleasing look is required.

Quality control is of utmost importance in the production of construction screws. Reputable manufacturers, such as Jiaxing Xinhongda Technology Co., Ltd., adhere to stringent quality standards throughout the manufacturing process. From sourcing high - grade raw materials to employing advanced manufacturing techniques and conducting rigorous testing, every step is carefully monitored to ensure that each screw meets or exceeds industry requirements. Tensile strength tests, shear strength tests, and thread durability tests are among the many assessments carried out to verify the performance and reliability of construction screws under various conditions.

In today’s digital age, the availability and accessibility of construction screws have been revolutionized. Online platforms and e - commerce marketplaces offer a vast selection of construction screws from numerous suppliers worldwide. Detailed product descriptions, technical specifications, customer reviews, and price comparisons are readily available, empowering contractors, builders, and DIY enthusiasts to make informed purchasing decisions. Many suppliers also offer bulk purchasing options, discounts, and fast shipping services, ensuring that construction projects of all sizes can obtain the right screws in a timely and cost - effective manner. Whether it’s a small - scale home renovation or a large - scale commercial construction project, the right construction screws are just a few clicks away.

In conclusion, construction screws are the unsung heroes of the construction world, playing a vital role in every stage of building projects. Their diverse types, carefully selected materials, innovative designs, stringent quality control, and easy availability make them essential for ensuring the success and longevity of structures. By choosing the appropriate construction screws, construction professionals can build with confidence, knowing that their creations will stand strong for years to come.