In the ever - evolving landscape of construction, screw construction has emerged as a fundamental and highly versatile aspect, playing a pivotal role in the assembly and reinforcement of structures. Screws used in construction are not merely simple fasteners; they are precision - engineered components that offer a wide range of benefits, making them indispensable in various building projects. These construction screws come in numerous types, each designed to meet specific requirements and applications within the construction domain. Wood screws, for example, are specifically crafted to penetrate and grip wooden materials securely. Their sharp points and fine or coarse threads are optimized to bite into the wood grain, providing a strong and reliable connection. Whether it’s framing a house, constructing wooden furniture within a building, or installing wooden fixtures, wood screws ensure that the wooden elements remain firmly joined together, withstanding the test of time and the stresses of normal use.

Self - tapping screws are another crucial type in screw construction. As the name implies, these screws have the ability to create their own threads as they are driven into materials such as metal, plastic, or even some types of composite materials. This eliminates the need for pre - tapping threads, saving valuable time and effort during the construction process. Self - tapping screws are widely used in metal framing, where they quickly and efficiently connect metal studs and tracks, providing the necessary strength and stability for walls and other structural components. They are also popular in the installation of drywall, as they can easily penetrate the gypsum board and secure it to the underlying framework.

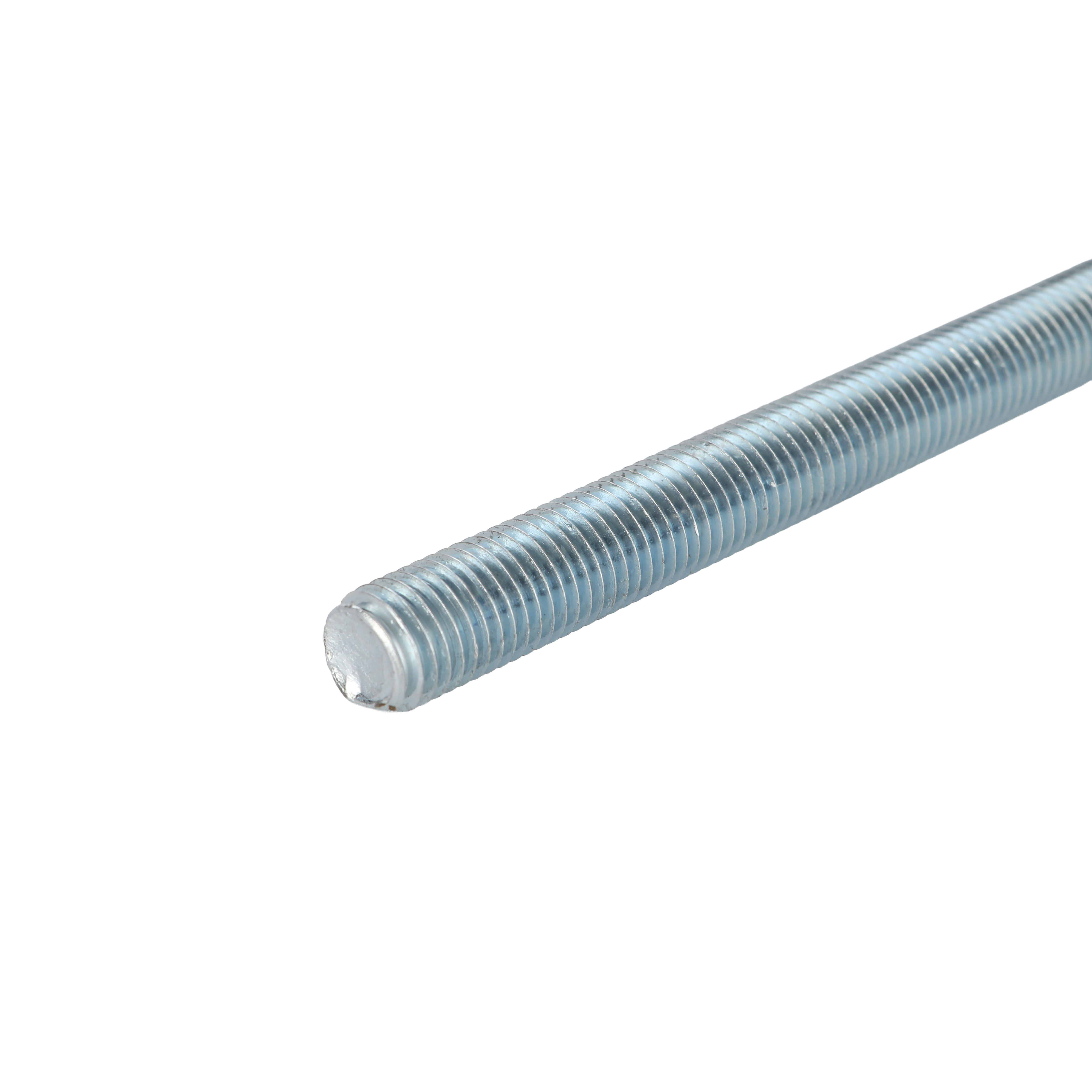

The materials used in screw construction are carefully selected to ensure durability, strength, and resistance to various environmental factors. Stainless steel screws are highly sought after due to their excellent corrosion resistance. Ideal for outdoor construction projects or areas with high humidity, such as bathrooms and kitchens, stainless steel screws can maintain their integrity over long periods, preventing rust and ensuring that the fastened components remain secure. Galvanized steel screws, coated with a protective layer of zinc, offer a cost - effective solution while still providing good corrosion protection. They are commonly used in general construction applications where exposure to the elements is moderate. Carbon steel screws, on the other hand, provide high tensile strength, making them suitable for heavy - duty construction tasks that require the screw to bear significant loads.

The design features of construction screws contribute significantly to their performance and ease of use. Different head styles, such as Phillips, flat, hex, and pan heads, serve various purposes. Phillips - head screws are convenient for general use as they can be driven with a standard screwdriver, although they may be prone to cam - out under high torque. Flat - head screws are preferred when a flush finish is required, as they can be countersunk into the material surface. Hex - head screws offer better torque transmission, allowing for higher tightening forces, which is essential in applications where a very secure connection is needed. Pan - head screws have a rounded top and are often used in applications where a more aesthetically pleasing appearance is desired.

In the construction industry, the quality of screws is of utmost importance. Inferior screws can lead to loose connections, structural weaknesses, and even project failures. Reputable manufacturers, like Jiaxing Xinhongda Technology Co., Ltd., implement strict quality control measures. From the raw material selection to the manufacturing process and final inspection, every step is carefully monitored to ensure that the screws meet or exceed industry standards. Rigorous testing for tensile strength, shear strength, and thread durability is conducted to guarantee that the construction screws can perform reliably under different conditions.

The availability and accessibility of construction screws have been greatly enhanced in the digital age. Online platforms and e - commerce marketplaces offer a vast array of construction screws from numerous suppliers. Detailed product descriptions, technical specifications, customer reviews, and price comparisons are readily available, enabling contractors, builders, and DIY enthusiasts to make informed purchasing decisions. Many suppliers also provide bulk purchasing options, discounts, and fast shipping services, which are highly beneficial for construction projects of all sizes. Whether it’s a small home improvement project or a large - scale commercial construction venture, the right construction screws can be easily sourced to meet the specific needs of the project.

In conclusion, screw construction is an integral part of the construction industry, offering a reliable, efficient, and versatile fastening solution. The diverse types, high - quality materials, specialized designs, and wide availability of construction screws make them essential for ensuring the strength, stability, and durability of structures. By choosing the appropriate construction screws and relying on the expertise of trusted manufacturers, construction professionals can ensure the success of their projects, creating buildings and infrastructure that stand the test of time.