119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

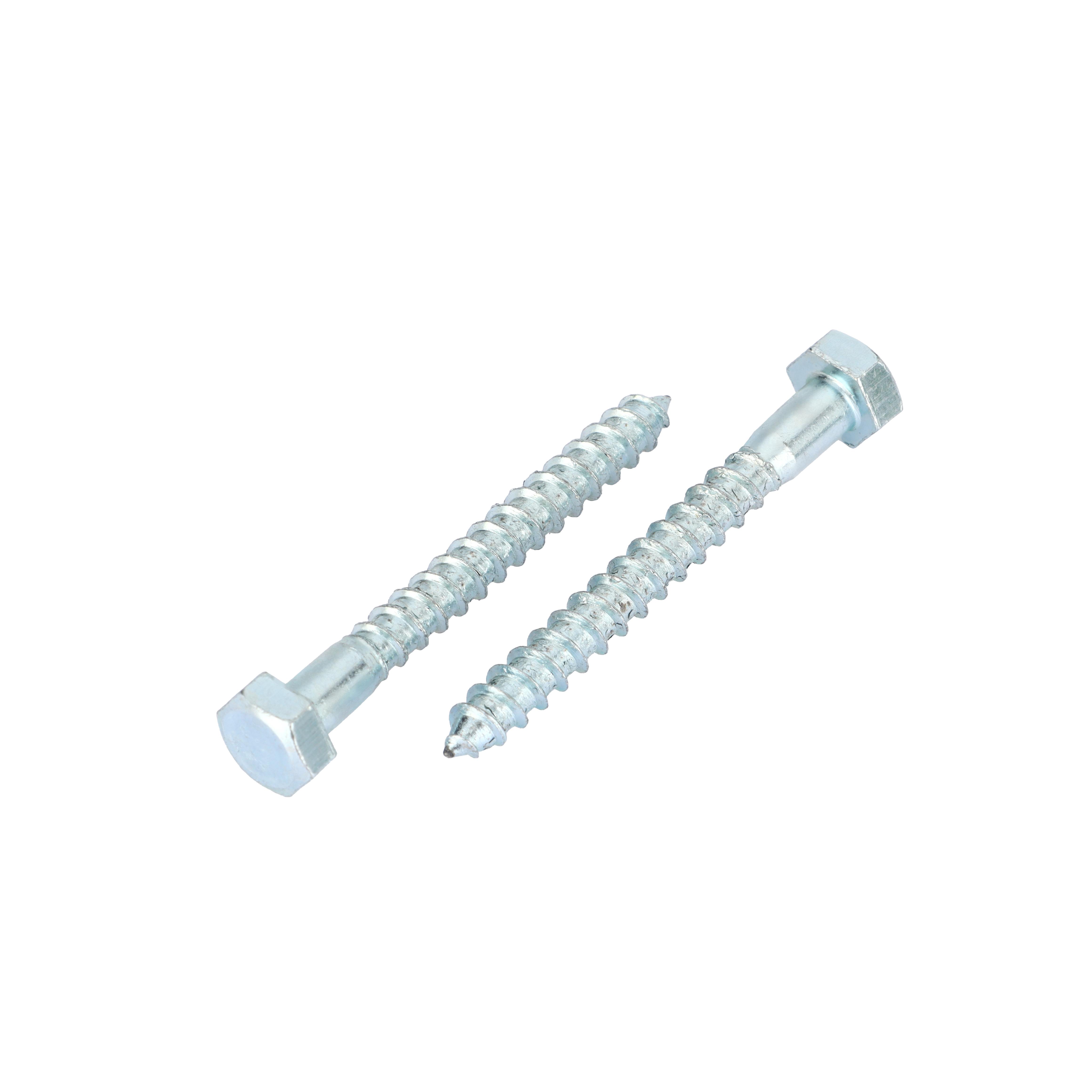

High tensile hex bolts are a cornerstone of modern industrial and construction applications, revered for their exceptional strength and reliability in demanding environments. These bolts are engineered to withstand extreme mechanical stresses, making them indispensable in projects where safety, durability, and long - term performance are non - negotiable. Crafted from premium materials such as high - strength alloy steels and heat - treated carbon steels, high tensile hex bolts are designed to deliver superior load - bearing capabilities and resistance to deformation, ensuring that they can handle the most rigorous conditions. The hexagonal head of these bolts serves as a key feature, providing a practical and efficient means of installation and adjustment. Its six - sided design allows for easy tightening and loosening with standard wrenches and sockets, ensuring a secure grip that minimizes the risk of slippage during operation. This feature is especially crucial when dealing with high - tensile bolts, as it enables workers to apply the necessary torque to achieve the required clamping force without the fear of damaging the bolt or compromising the integrity of the joint. The flat surfaces of the hexagon also ensure an even distribution of force, reducing the likelihood of stress concentrations that could lead to premature failure. In the construction industry, high tensile hex bolts play a vital role in the assembly of large - scale structures. They are commonly used in the connection of steel beams, columns, and trusses in buildings, bridges, and other infrastructure projects. These bolts provide the strength and stability needed to support heavy loads and resist forces such as tension, compression, and shear. For example, in the construction of skyscrapers, high tensile hex bolts are used to secure the structural components together, ensuring that the building can withstand the forces of wind, earthquakes, and its own weight. Their high tensile strength allows for a more efficient use of materials, reducing the overall weight of the structure while maintaining its structural integrity. In the automotive and aerospace sectors, high tensile hex bolts are equally essential. In automotive manufacturing, they are used in critical applications such as engine assembly, chassis construction, and suspension systems. These bolts need to endure the constant vibrations, heat, and mechanical stresses generated during vehicle operation, and their high tensile strength ensures that they can maintain a secure connection over the lifespan of the vehicle. In aerospace, where precision and reliability are of utmost importance, high tensile hex bolts are used to fasten critical components of aircraft, including the fuselage, wings, and engines. These bolts must be able to withstand the extreme conditions of flight, such as high altitudes, rapid changes in temperature, and aerodynamic forces, without compromising their strength or integrity. The manufacturing process of high tensile hex bolts is highly specialized and严格的. Advanced forging techniques are employed to shape the bolts, followed by heat treatment processes to enhance their mechanical properties. Heat treatment involves heating the bolts to a specific temperature and then cooling them rapidly, which improves their strength, hardness, and toughness. Stringent quality control measures are implemented at every stage of production to ensure that each high tensile hex bolt meets or exceeds industry standards. Non - destructive testing methods, such as ultrasonic testing and magnetic particle inspection, are used to detect any internal defects or flaws that could affect the performance of the bolt. High tensile hex bolts are available in a wide range of sizes, grades, and finishes to meet the specific requirements of different applications. Different grades of high tensile bolts offer varying levels of strength, with higher - grade bolts capable of withstanding greater loads. For example, grade 8.8 and grade 10.9 are common high - tensile bolt grades used in many industrial applications, each offering specific strength and performance characteristics. Various surface finishes, such as zinc plating, hot - dip galvanizing, and black oxide coating, can be applied to enhance the corrosion resistance and aesthetic appeal of the bolts. In addition to their mechanical properties, high tensile hex bolts also offer economic benefits. Their durability and long - lasting performance reduce the need for frequent replacements, saving both time and money in the long run. Moreover, the widespread availability of these bolts means that they can be easily sourced at competitive prices, making them a cost - effective fastening solution for businesses and individuals alike. Whether you are a professional contractor, an automotive engineer, or a DIY enthusiast, high tensile hex bolts are an essential part of your toolkit. Their reliability, strength, and ease of use make them the go - to choice for a multitude of applications. With their exceptional performance and durability, high tensile hex bolts provide the peace of mind that your projects will be secure and stable, no matter the challenges they may face.