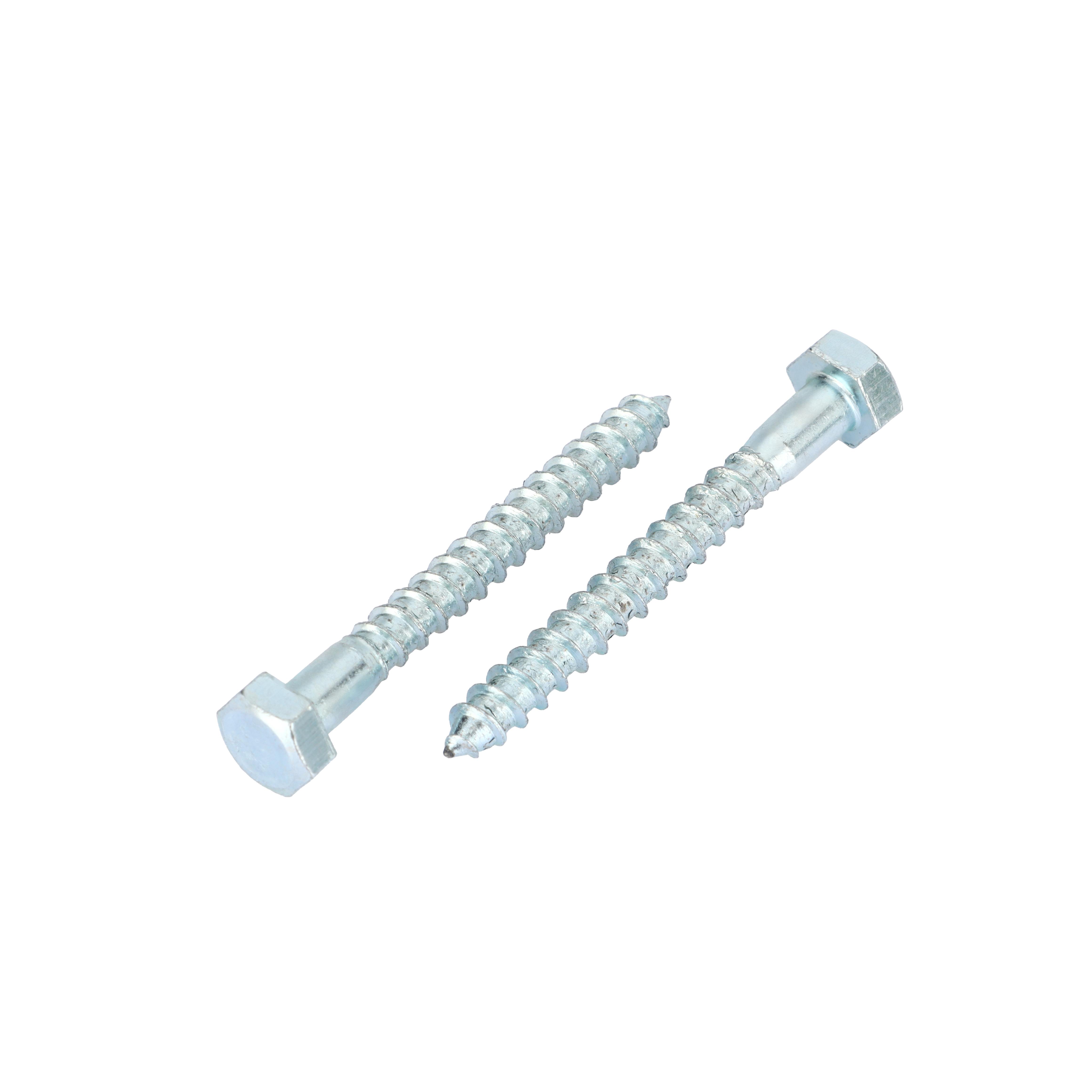

In the dynamic landscape of construction, manufacturing, and countless DIY projects, hex screws have firmly established themselves as essential fastening solutions, renowned for their reliability, versatility, and ease of use. These screws, distinguishable by their six - sided heads, offer a unique blend of functionality that caters to a wide array of applications across various industries. Hex screws are crafted from an assortment of high - quality materials, each selected based on the specific demands of different projects. Stainless steel hex screws, for instance, are highly prized for their exceptional corrosion resistance, making them the go - to choice for outdoor installations, marine applications, and environments with high humidity, such as bathrooms or swimming pool areas. They can endure exposure to moisture, saltwater, and other corrosive elements over extended periods without rusting or degrading, ensuring that the fastened components remain securely connected. Carbon steel hex screws, on the other hand, provide excellent tensile strength, allowing them to bear heavy loads and are commonly utilized in general construction tasks, from securing wooden frames in residential buildings to assembling metal structures in industrial settings. Galvanized hex screws, coated with a protective layer of zinc, offer a cost - effective yet durable option, suitable for a wide range of indoor and outdoor applications where moderate protection against corrosion is required.

The design of hex screws is optimized to enhance both installation efficiency and performance. The hexagonal head shape allows for a firm grip when using wrenches or socket tools, enabling users to apply higher torque levels compared to other screw head types. This feature ensures that hex screws can be tightened securely, creating robust and stable connections that can withstand vibrations, mechanical stress, and heavy loads. Moreover, hex screws come in a vast range of sizes, varying in diameter and length, to accommodate different materials and thicknesses. Whether it’s a small - scale project that requires tiny hex screws to fasten delicate components or a large - scale construction endeavor that demands massive hex screws to join substantial structural elements, there is a suitable option available. The thread patterns of hex screws are also carefully engineered; coarse threads are ideal for quick insertion and applications where rapid assembly is needed, such as in wooden materials where they can easily bite into the grain. Fine threads, on the other hand, provide a more precise and secure fit, making them perfect for applications in metalworking, where a tight and vibration - resistant connection is crucial.

In the manufacturing industry, hex screws play a vital role in the assembly of machinery, equipment, and appliances. They ensure that various parts are held together firmly, preventing any unwanted movement or displacement that could lead to mechanical failures or malfunctions. In the automotive sector, hex screws are used to secure engine components, suspension systems, and body panels, contributing significantly to the overall safety and performance of vehicles. Similarly, in the electronics industry, small hex screws are employed to assemble circuit boards, enclosures, and other intricate components, ensuring precision and reliability. For DIY enthusiasts and hobbyists, hex screws offer a convenient and accessible fastening solution for a multitude of projects, from building furniture and crafting decorative items to repairing household appliances and equipment.

Quality control is of utmost importance in the production of hex screws. Reputable manufacturers, like Jiaxing Xinhongda Technology Co., Ltd., adhere to strict quality standards throughout the manufacturing process. From sourcing premium raw materials to employing advanced manufacturing techniques and conducting rigorous testing, every step is carefully monitored to ensure that each hex screw meets or exceeds industry specifications. Tensile strength tests, shear strength tests, and thread durability tests are among the many evaluations carried out to verify the performance and reliability of hex screws under different conditions. Additionally, meticulous inspections for dimensional accuracy are conducted to ensure proper fitment with corresponding nuts and holes, preventing issues such as loose connections or difficulty in installation.

The widespread availability and accessibility of hex screws have been further enhanced in the digital age. Online platforms and e - commerce marketplaces offer a vast selection of hex screws from numerous suppliers worldwide. Detailed product descriptions, technical specifications, customer reviews, and price comparisons are readily available, empowering buyers to make informed purchasing decisions. Many suppliers also provide bulk purchasing options, discounts, and fast shipping services, making it convenient and cost - effective for contractors, manufacturers, and DIYers to acquire the necessary hex screws for their projects, regardless of size or complexity. Whether it’s a small repair job at home, a large - scale industrial production run, or a construction project of any magnitude, the right hex screws are just a few clicks away.

In conclusion, hex screws are indispensable components in a multitude of industries and projects, offering a reliable, versatile, and efficient fastening solution. Their diverse material options, optimized design features, stringent quality control, and wide availability make them a cornerstone for creating secure and long - lasting connections. By choosing high - quality hex screws from trusted manufacturers, professionals and enthusiasts alike can ensure the success and durability of their work, whether it’s constructing a sturdy building, assembling complex machinery, or completing a creative DIY project.