119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

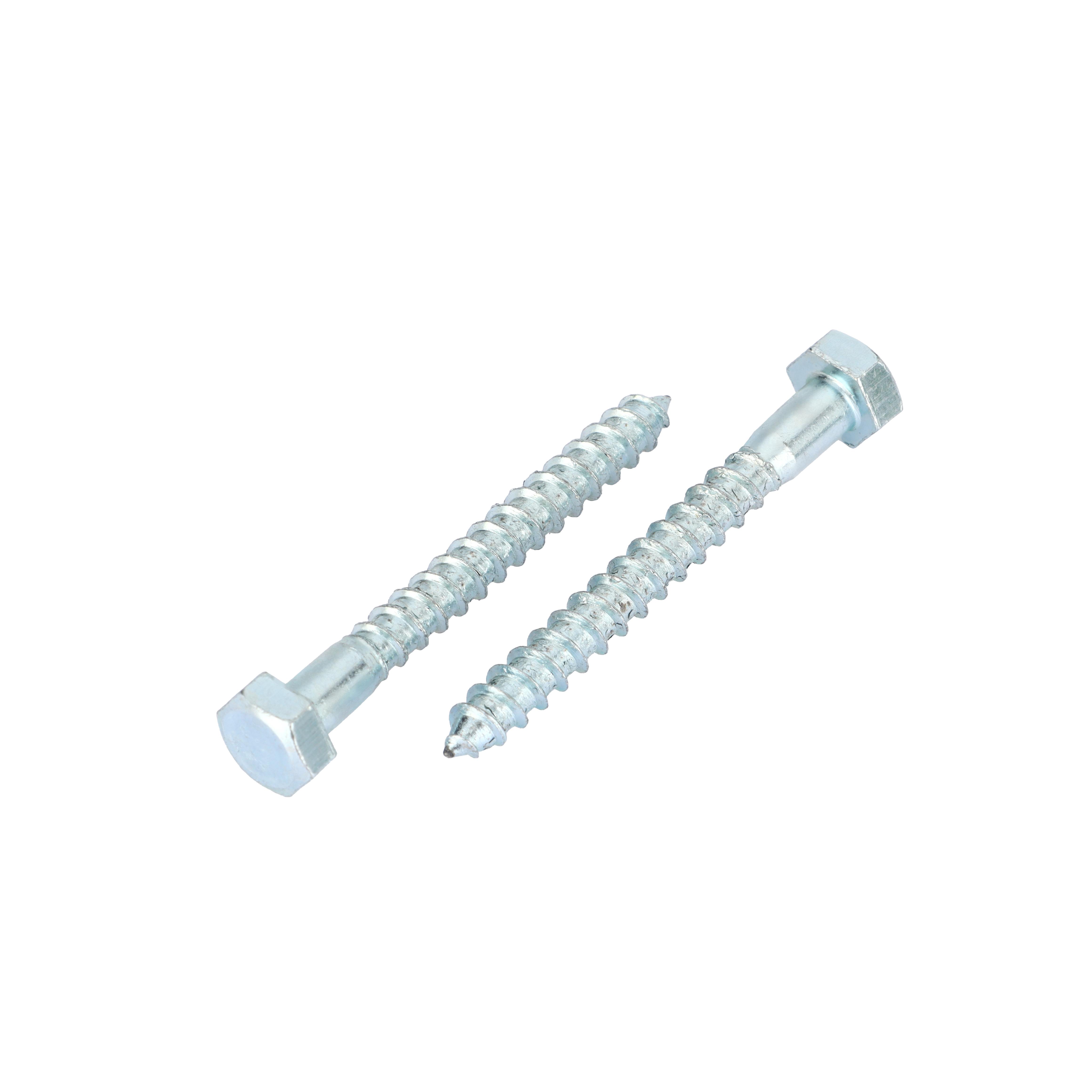

Aluminum hex bolts have emerged as a highly sought - after fastening solution across a diverse range of industries, thanks to their unique combination of properties that offer a perfect balance between functionality, durability, and lightweight design. These bolts, characterized by their hexagonal heads and aluminum construction, present numerous advantages that make them an ideal choice for applications where traditional steel bolts might not be the most suitable option. Crafted from high - quality aluminum alloys, aluminum hex bolts possess excellent corrosion resistance, low density, and good strength - to - weight ratio, making them suitable for both indoor and outdoor use in various environmental conditions. The hexagonal head design of aluminum hex bolts, similar to their counterparts in other materials, provides significant practical benefits. It allows for easy and efficient tightening and loosening with standard wrenches and sockets, ensuring a secure grip during installation and removal processes. This feature is crucial as it enables workers to apply the necessary torque accurately, facilitating quick and hassle - free assembly and disassembly operations. The flat sides of the hexagon also contribute to a stable application of force, distributing stress evenly and reducing the risk of slippage, which is essential for maintaining the integrity of the fastened components. In the aerospace industry, aluminum hex bolts play a vital role. The aerospace sector places a premium on lightweight materials without sacrificing strength and reliability, and aluminum hex bolts fit the bill perfectly. Their low density helps reduce the overall weight of aircraft, which in turn improves fuel efficiency and performance. These bolts are used in various critical areas of aircraft construction, such as wing assemblies, fuselage structures, and engine mounts. Despite their lightweight nature, aluminum hex bolts can withstand the extreme mechanical stresses and vibrations experienced during flight, as well as the harsh environmental conditions at high altitudes, including rapid temperature changes and exposure to moisture and corrosive elements. The automotive industry also benefits greatly from aluminum hex bolts. With the growing emphasis on fuel efficiency and reducing vehicle emissions, the use of lightweight materials has become a key strategy. Aluminum hex bolts are employed in automotive manufacturing for applications such as engine components, suspension systems, and body assemblies. By replacing heavier steel bolts with aluminum counterparts, automakers can reduce the vehicle's curb weight, leading to improved fuel economy and enhanced performance. Moreover, the corrosion resistance of aluminum hex bolts ensures that they maintain their functionality and appearance over time, even when exposed to road salt, moisture, and other contaminants commonly encountered on the road. In the construction and infrastructure sectors, aluminum hex bolts find application in a variety of projects. They are particularly useful in outdoor structures where corrosion resistance is a major concern, such as bridges, outdoor signage, and marine - related constructions. Unlike steel bolts, which are prone to rust and corrosion when exposed to moisture and saltwater, aluminum hex bolts can maintain their structural integrity for extended periods without the need for frequent maintenance or replacement. This not only reduces the overall cost of ownership but also ensures the safety and longevity of the structures. Additionally, in architectural applications where aesthetics are important, the smooth and clean appearance of aluminum hex bolts can enhance the visual appeal of the construction. The manufacturing process of aluminum hex bolts involves advanced techniques to ensure consistent quality and performance. High - grade aluminum alloys are carefully selected based on the specific requirements of different applications, and then formed through processes such as forging or extrusion. After shaping, the bolts may undergo additional treatments such as heat treatment to improve their mechanical properties, and surface finishing processes like anodizing or powder coating to further enhance their corrosion resistance and appearance. Stringent quality control measures are implemented throughout the manufacturing process to ensure that each aluminum hex bolt meets or exceeds industry standards. Aluminum hex bolts are available in a wide range of sizes, thread specifications, and grades to accommodate different fastening needs. Different aluminum alloys offer varying levels of strength and corrosion resistance, allowing users to choose the most appropriate bolt for their specific application. For example, alloys with higher copper content tend to have greater strength, while those with more magnesium and silicon offer enhanced corrosion resistance. This versatility in options ensures that there is an aluminum hex bolt suitable for every project, whether it's a small - scale DIY task or a large - scale industrial application. In conclusion, aluminum hex bolts have carved out a niche for themselves as a reliable and versatile fastening solution in multiple industries. Their lightweight yet strong construction, excellent corrosion resistance, and ease of use make them an attractive alternative to traditional steel bolts. Whether it's in the high - tech aerospace industry, the ever - evolving automotive sector, or the vast construction and infrastructure domain, aluminum hex bolts continue to prove their worth, providing secure and long - lasting connections that meet the demands of modern applications.