119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

119 County Road, Tongyuan Town, Haiyan County, Jiaxing City, Zhejiang Province +86 180 5863 3730 [email protected]

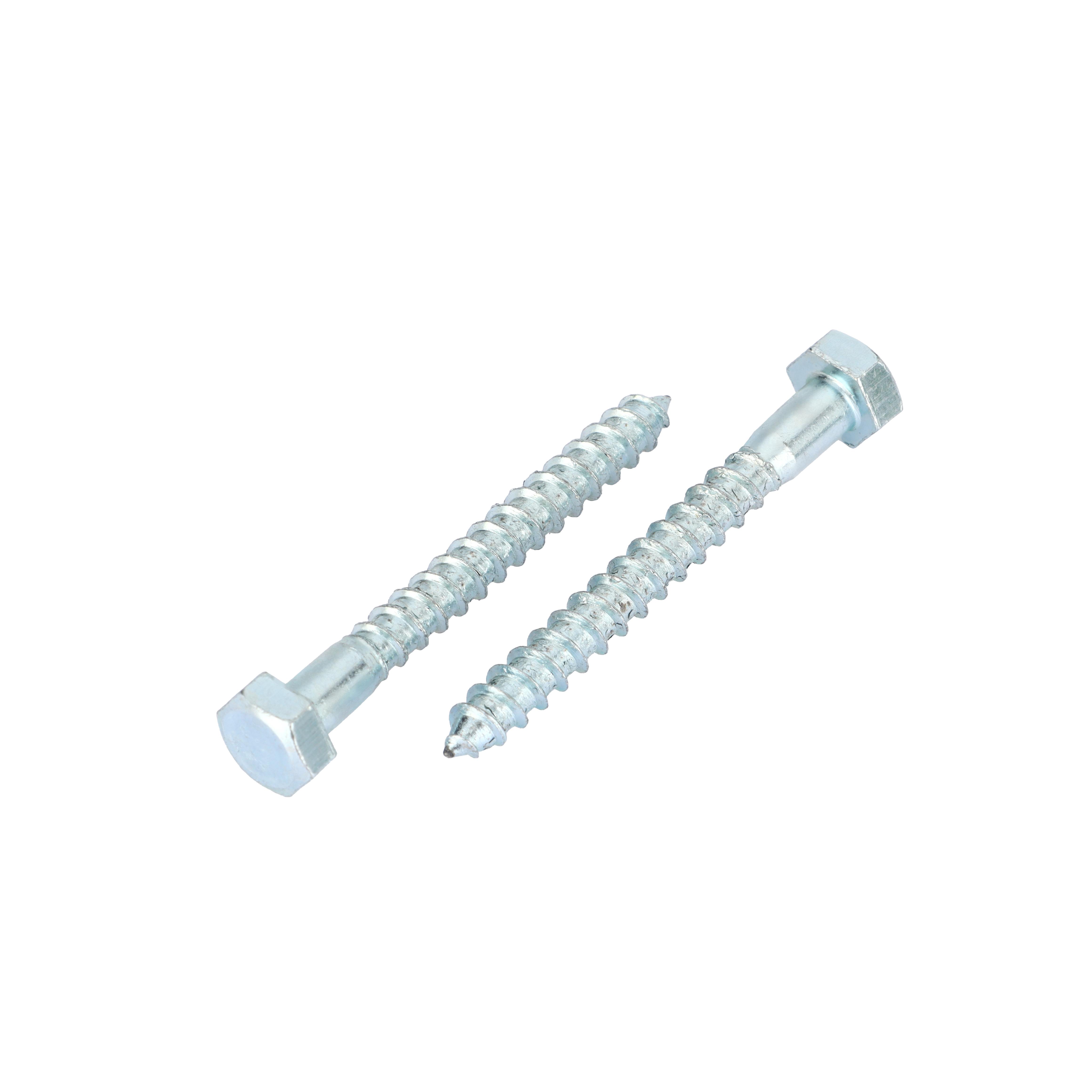

Hexagon head bolts are an integral and highly versatile component in the world of fastening solutions, widely utilized across a multitude of industries due to their practical design and exceptional functionality. These bolts, characterized by their six - sided head and threaded shank, offer a perfect blend of strength, ease of use, and reliability, making them an essential choice for countless applications. Crafted from a variety of high - quality materials such as carbon steel, stainless steel, alloy steel, brass, and aluminum, hexagon head bolts are engineered to meet the diverse demands of different environments and mechanical requirements. The hexagonal shape of the bolt head provides several significant advantages that contribute to its widespread popularity. Firstly, it allows for easy and efficient tightening and loosening using standard wrenches and sockets. The six - flat sides of the hexagon provide a secure grip, enabling workers to apply the necessary torque without the risk of slippage, even in challenging conditions or when dealing with high - force applications. This feature is crucial in both industrial settings, where precision and speed in assembly and disassembly are paramount, and in DIY projects, where accessibility and convenience are highly valued. Moreover, the symmetrical design of the hexagon head ensures an even distribution of force during operation, reducing the likelihood of stress concentrations that could lead to premature failure of the bolt or damage to the materials being fastened. In the construction industry, hexagon head bolts play a vital role in the assembly of various structures. They are extensively used to connect steel beams, columns, and other structural components in buildings, bridges, and large - scale infrastructure projects. These bolts provide the strength and stability required to support heavy loads and resist forces such as tension, compression, and shear. For instance, in high - rise building construction, hexagon head bolts are employed to secure the steel frames together, ensuring the structural integrity of the entire building and its ability to withstand external forces like wind and earthquakes. Their reliable performance and ease of installation make them indispensable for construction professionals aiming to complete projects efficiently and safely. In the automotive and aerospace sectors, hexagon head bolts are equally indispensable. In automotive manufacturing, they are used in every aspect of vehicle assembly, from engine components and transmission systems to chassis and body structures. These bolts must endure the constant vibrations, heat, and mechanical stresses generated during vehicle operation, and their high - quality construction and robust design ensure long - lasting performance and safety. In aerospace, where precision and reliability are of utmost importance, hexagon head bolts are used to fasten critical parts of aircraft, including the fuselage, wings, and engines. They need to withstand extreme conditions such as high altitudes, rapid temperature changes, and aerodynamic forces, and their ability to maintain a secure connection is crucial for the overall functionality and safety of the aircraft. The manufacturing process of hexagon head bolts is highly precise and involves advanced techniques to ensure consistent quality. Bolts are typically formed through processes such as forging, which imparts strength and durability by aligning the grain structure of the material, or machining, which allows for high - precision dimensional control. After shaping, heat treatment processes may be applied to enhance the mechanical properties of the bolts, such as increasing their strength and hardness. Stringent quality control measures are implemented at every stage of production, including inspections for proper thread formation, head geometry, and material integrity. Different grades of hexagon head bolts are available, each with specific strength ratings to suit various application requirements. For example, higher - grade bolts are suitable for heavy - duty applications where high tensile strength is needed, while lower - grade bolts can be used for lighter - load situations. Hexagon head bolts are available in a vast range of sizes, lengths, and thread specifications to accommodate diverse fastening needs. This wide variety allows for customization based on the specific requirements of different projects, whether it's a small - scale repair job on a household appliance or a large - scale industrial installation. Additionally, various surface treatments can be applied to hexagon head bolts to enhance their performance and appearance. Zinc plating, hot - dip galvanizing, and black oxide coating are common treatments that provide corrosion resistance, protecting the bolts from rust and degradation, especially in outdoor or harsh - environment applications. In conclusion, hexagon head bolts are a fundamental and highly reliable fastening solution that has stood the test of time across numerous industries. Their unique combination of a practical hexagonal head design, high - quality materials, and precise manufacturing processes makes them a trusted choice for professionals and enthusiasts alike. Whether it's building a skyscraper, assembling a high - performance vehicle, or fixing a simple piece of machinery, hexagon head bolts offer the strength, ease of use, and durability required to ensure a successful and long - lasting connection. Their versatility and consistent performance make them an essential component in any toolkit, providing the peace of mind that projects will be completed with secure and reliable fastenings.