What Are High Tensile Bolts? Understanding Mechanical Properties and Grading

Definition and Characteristics of High-Tensile Fasteners

High tensile bolts are special fasteners built to handle serious mechanical stress without breaking down. These bolts typically come from alloy steels including carbon, chromium, sometimes even boron mixtures. After going through specific heat treatment processes, they end up being about two to four times stronger than regular bolts on the market. The extra strength means these bolts can carry much heavier loads, which is why engineers rely on them so heavily for important structures. We see them holding together massive bridge components, keeping industrial machines running smoothly, and providing stability in buildings meant to resist earthquakes. Without this kind of reinforcement, many modern construction projects simply wouldn't be possible.

Key Mechanical Properties: Tensile Strength, Yield Strength, and Young’s Modulus

Three core metrics define high tensile bolt performance:

- Tensile strength: The force required to break the bolt, ranging from 800 MPa (grade 8.8) to 1,200 MPa (grade 12.9)

- Yield strength: The threshold for permanent deformation, typically around 80% of tensile strength in grade 10.9 bolts

- Young’s modulus: A measure of stiffness under load, approximately 200 GPa for steel, ensuring minimal joint displacement

Higher-grade bolts maintain structural integrity under dynamic stresses such as wind loads up to 150 mph, as defined by ISO 898-1 international standards.

Bolt Grades Explained: Comparing 8.8, 10.9, and 12.9 Performance Levels

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Common Applications |

|---|---|---|---|

| 8.8 | 800 | 640 | Light bridges, machinery |

| 10.9 | 1,040 | 940 | Skyscrapers, wind turbines |

| 12.9 | 1,200 | 1,080 | Aerospace, seismic bracing |

Grade 10.9 bolts, with 1,040 MPa tensile strength, serve as an industry benchmark, providing a 20% safety margin over typical design loads in steel frame construction.

Material Composition and Manufacturing Standards for Reliable Performance

Alloy Steel, Stainless Steel, and Special Alloys in High Tensile Bolt Production

The real power behind high tensile bolts comes down to the special metal mixtures they're made from. Take alloy steels for instance, those combinations of chromium with molybdenum or nickel mixed with chromium can reach incredible tensile strengths over 1,000 MPa yet still be shaped and worked with relative ease. When dealing with harsh environments where corrosion is a concern, engineers often turn to stainless steel options like AISI 316. These materials stand up much better against chlorides than regular carbon steel does, cutting down on rust problems by around two thirds according to industry tests. For situations that push materials to their limits, look no further than the aerospace and nuclear industries which rely on nickel based superalloys such as Inconel 718. What makes these so valuable? They keep their shape and strength even when exposed to blistering heat, maintaining structural integrity all the way up to temperatures reaching 700 degrees Celsius.

ASTM A325 and A490 Standards: Ensuring Consistency and Quality Control

The reliability of structural fasteners depends heavily on manufacturing standards that govern their production. Take ASTM A325 bolts for instance they go through quench and temper treatment to reach at least 120 ksi tensile strength. Then there are ASTM A490 bolts, often seen in earthquake-prone areas, which need even stronger specs ranging from 150 to 173 ksi tensile strength plus passing Charpy impact tests as part of quality checks. Independent verification plays a big role here too, keeping an eye on things like chemical makeup within ±0.03% carbon content and hardness levels between HRC 33 and 39 for Grade C ASTM A490 bolts specifically. These controls help reduce how much variation exists between different batches of bolts, which matters when building structures that need consistent performance year after year.

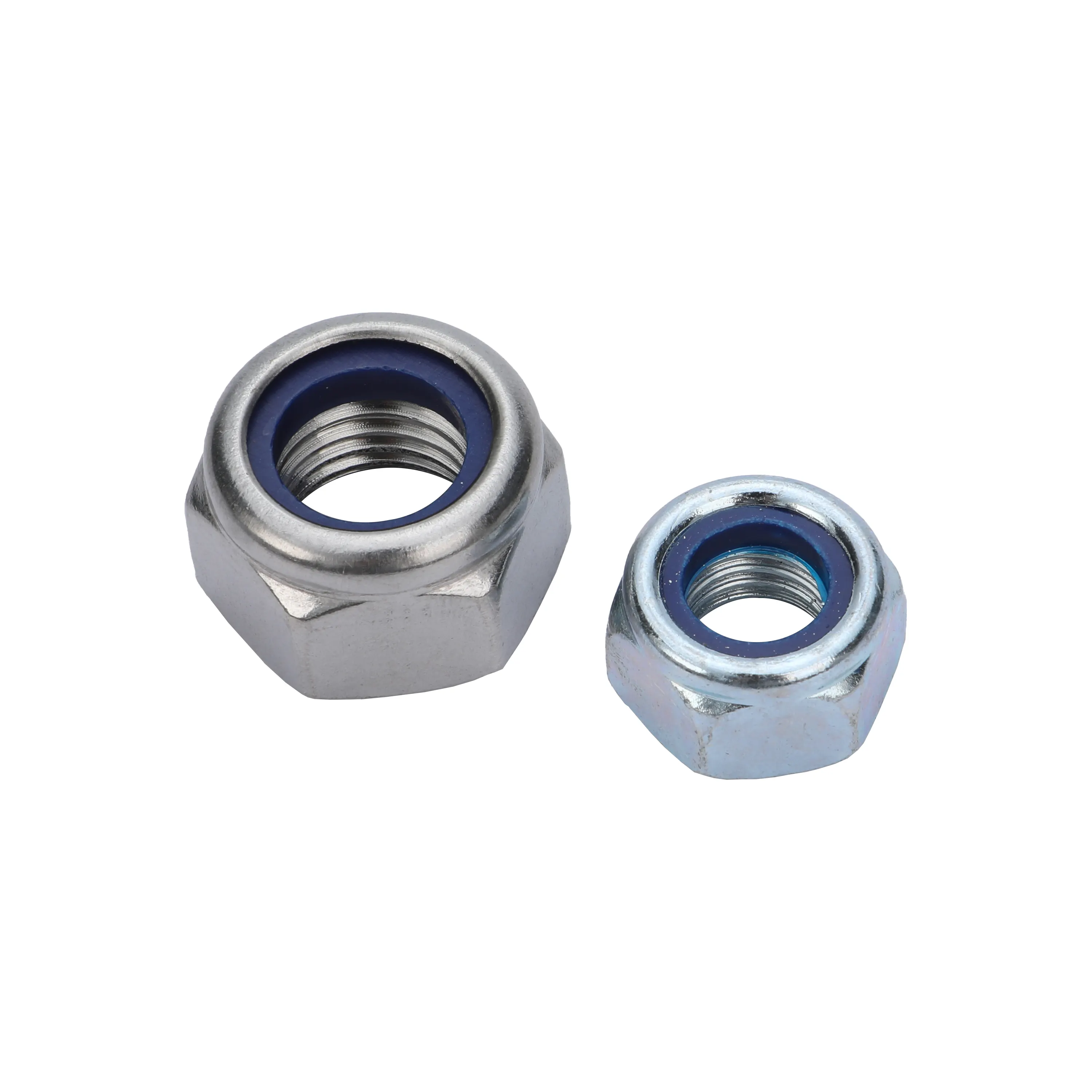

Matching High-Strength Bolts With Compatible Nuts and Washers

Getting system reliability right starts with matching components correctly. Take Grade 10.9 bolts for instance they need Class 10 nuts that have been hardened between 38 and 45 HRC to stand up against thread stripping when loaded at around 80% of their proof strength. Belleville washers play an important role too, keeping clamp force stable across extreme temperatures from minus 40 degrees Celsius all the way up to 300°C. These washers actually hold onto 85 to 92% of their initial tension even after going through multiple thermal cycles. When engineers specify compatible hardware instead of mixing different grades, they can cut down stress concentrations by as much as 40% over mismatched parts. This makes a real difference in long term performance for critical applications where failure isn't an option.

Enhancing Structural Stability: The Role of High Tensile Bolts in Load Management

How Tensile Strength Improves Load-Bearing Capacity Under Static and Dynamic Loads

High tensile bolts handle both static and moving loads really well because they have strong yield strength around 940 MPa for grade 10.9 bolts and maintain good stiffness with Young's modulus about 210 GPa. These properties mean buildings and other structures can hold up under constant weight while still standing up to repeated stress from things like wind blowing back and forth without bending out of shape. When looking at places where vibrations are common, think wind turbine foundations for instance, bolts that meet rating 8.8 or better last about 27 percent longer before wearing out compared to regular fasteners without ratings. A recent paper published in the International Journal of Mechanical Sciences backs this up, showing why engineers specify these stronger bolts for critical applications where failure isn't an option.

Preventing Joint Failure in Critical Connections Using Grade 10.9 Bolts

Grade 10.9 bolts have a tensile strength around 1,040 MPa which is roughly 47 percent better than what we see in grade 8.8 fasteners. These bolts really matter for those critical connections in areas prone to earthquakes or in skyscrapers where failure isn't an option. If properly tightened according to the ASTM A490 specs, these bolts hold things together much better. Tests show they cut down on slipping problems by about two thirds in those important beam to column joints. Real world testing also shows these bolts keep everything intact even under loads reaching almost 85% of what they can actually handle before breaking. That kind of performance gives engineers peace of mind compared to cheaper bolt options that just don't measure up in such demanding situations.

Critical Applications in Bridges, Buildings, and Seismic Zones

High tensile bolts are indispensable in modern infrastructure, delivering exceptional load management and resilience where failure is not an option.

High Tensile Bolts in Bridge and Steel Frame Construction for Long-Term Reliability

Grade 10.9 bolts play a critical role in securing steel girders and connecting piers on bridges, standing up against not just regular traffic but also fierce winds that can reach speeds around 150 miles per hour. According to a recent report from structural engineers back in 2023, bridges built with ASTM A490 bolts actually cost about 92 percent less to maintain over twenty years than their counterparts using standard fasteners. This makes a big difference for budget planning! When we look at steel framed buildings too, these high strength bolts make all the difference in creating solid beam to column joints. Take the famous San Francisco-Oakland Bay Bridge retrofit project as an example. The engineers there chose these specialized bolts because they needed something that could last through salt air corrosion along the coast. And guess what? Those bolts have been performing reliably for more than half a century now without any major issues.

Use in Skyscrapers, Wind Turbines, and Industrial Structures

High tensile bolts play a critical role in moment resisting frames of skyscrapers. Take the Shanghai Tower as an example it actually used over 2.1 million grade 12.9 bolts throughout its composite steel concrete core structure. When we look at wind turbines, manufacturers go for grade 10.9 bolts specifically for those tower flange joints because they need something that can handle fatigue. These bolts have to withstand around 100 million load cycles over their 25 year service life, which is pretty impressive when you think about it. The industrial world relies heavily on these specialized fasteners across various sectors where structural integrity really counts.

- Crane runway beams handling 5,000+ daily lifts

- Pressure vessel flanges maintaining seals at 1,500 psi

- Heavy machinery foundations damping vibrations up to 15 Hz

Performance in Seismic-Prone Areas and High-Risk Structural Zones

California's seismic retrofitting work often incorporates high tensile strength bolts which can boost energy dissipation in older buildings anywhere from 40% to 60% according to some studies out of Caltech back in 2022. When those big quakes hit Ridgecrest in 2019, the grade 8.8 bolts held their connections together even through the 7.1 magnitude shaking because they were designed to deform plastically in a controlled way. For areas at risk from tsunamis too, many engineers are starting to combine 12.9 grade bolts with what they call sacrificial threads. This creates safety systems that won't let buildings just suddenly fall apart when multiple hazards strike at once.

Safety, Durability, and Limitations Under Extreme Conditions

Despite their strength, high tensile bolts have performance boundaries that demand careful engineering consideration in extreme environments.

Ensuring safety and reliability in high-stress engineering environments

Reliability stems from strict adherence to ASTM manufacturing standards and precision installation. Structural studies show grade 10.9 bolts retain 92% of clamp force under seismic loading, significantly outperforming lower-grade fasteners, which retain only 67%. This consistency makes them essential in earthquake-resistant designs.

Fire resistance of bolted steel connections and thermal performance concerns

While steel has inherent fire resistance, elevated temperatures degrade bolt performance. Grade 8.8 bolts lose 50% of their yield strength at 400°C, and electroplated coatings fail within 15 minutes under direct flame. To extend connection integrity during fires, engineers often apply ceramic thermal barriers.

Performance limitations under extreme heat: A technical analysis

Prolonged exposure above 450°C triggers irreversible metallurgical changes in most high tensile bolts, reducing elongation capacity by 60—80%. In power plants and chemical processing facilities, where such conditions are common, nickel-based superalloys are preferred to avoid catastrophic fastener failure.

FAQ

What are high tensile bolts?

High tensile bolts are specialized fasteners made from alloy steels, designed to withstand high levels of mechanical stress and provide enhanced load carrying capacity.

Why are high tensile bolts preferred in construction?

They are preferred due to their higher strength, allowing them to support heavier loads and provide stability in structures such as bridges, buildings, and industrial machinery.

What is the significance of bolt grading like 8.8, 10.9, and 12.9?

The grades indicate tensile and yield strength levels, with higher numbers representing greater strengths, making them suitable for different applications like bridges, skyscrapers, and aerospace installations.

How do high tensile bolts improve structural stability?

Their excellent tensile strength and stiffness improve load-bearing capacity, allowing structures to withstand static and dynamic loads, including vibrations and wind pressure.

Where are high tensile bolts commonly used?

They are commonly used in infrastructure projects such as bridges, skyscrapers, wind turbines, and in seismic zones for retrofitting to improve resilience against earthquakes and other hazards.

Table of Contents

- What Are High Tensile Bolts? Understanding Mechanical Properties and Grading

- Material Composition and Manufacturing Standards for Reliable Performance

- Enhancing Structural Stability: The Role of High Tensile Bolts in Load Management

- Critical Applications in Bridges, Buildings, and Seismic Zones

- Safety, Durability, and Limitations Under Extreme Conditions