Understanding Anchor Bolt Types and Structural Applications

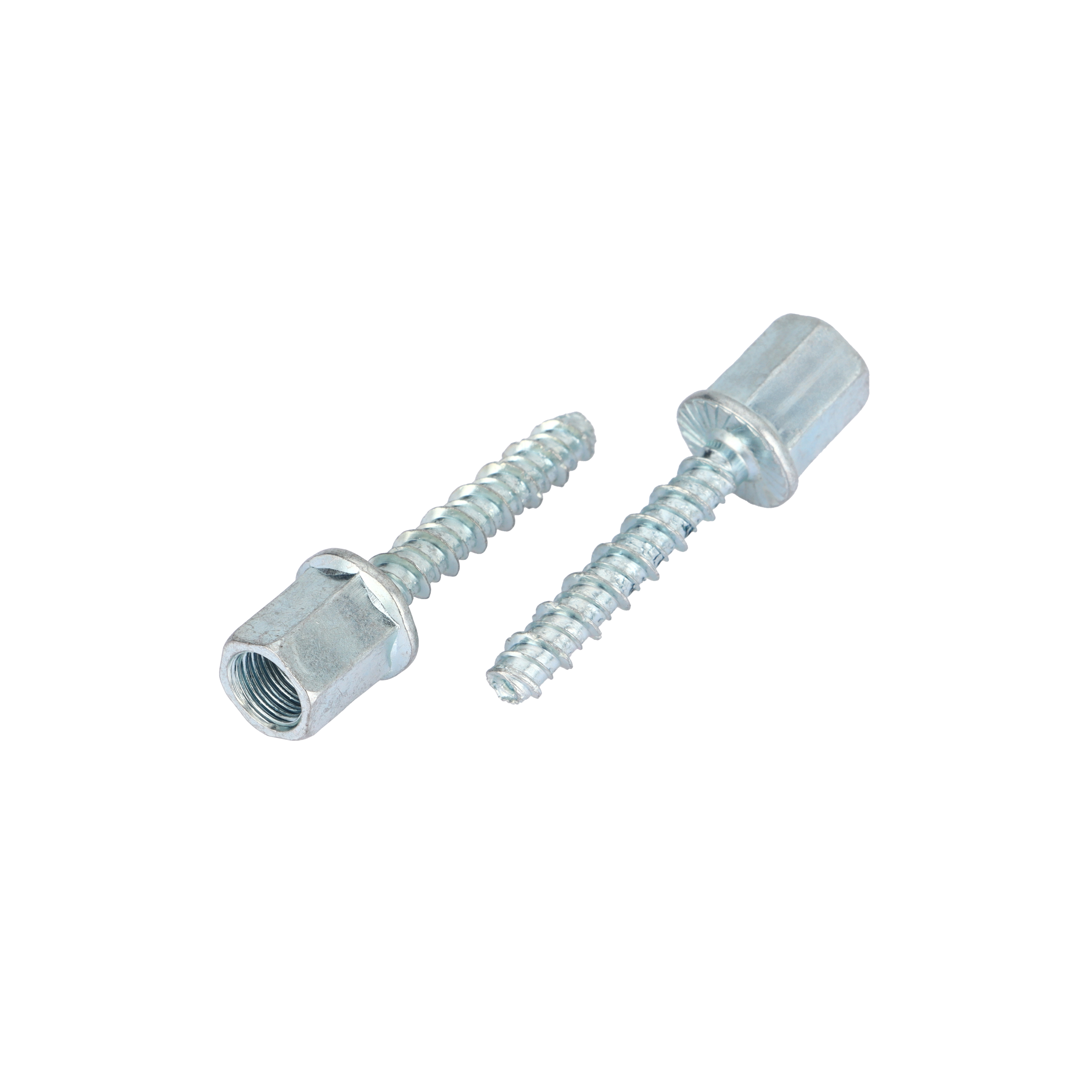

Common Types of Anchor Bolts: L-Bolts, J-Bolts, and Headed Studs

In structural fastening work, L-bolts, J-bolts, and headed studs play critical roles. The L-bolt gets its name from the right angle bend and is commonly set into concrete foundations to hold columns firmly against footings. For projects involving softer materials, contractors often prefer J-bolts because their curved shape grabs better in these substrates. When it comes to steel structures meeting concrete bases, headed studs are usually the go-to choice. These are generally welded onto base plates and spread loads more evenly across connections. According to recent studies referenced in ASTM F1554-22 standards, engineers have found that headed anchors actually cut down on concrete breakouts by around 35% when compared with traditional bent bolt designs. This makes them particularly valuable for ensuring long term stability in construction projects.

Cast-in-Place vs. Post-Installed Anchor Bolts: Key Differences and Use Cases

Cast-in-place anchors are installed during concrete pouring and are preferred for critical applications such as seismic bracing. Post-installed anchors—mechanical expansion or epoxy-bonded types—allow for retrofitting but require strict adherence to hole dimensions; undersized holes can reduce pullout strength by up to 25% (ACI 318-23).

F1554 Anchor Bolts: Comparing Grades 55 and 105 for Structural Reliability

The ASTM F1554 Grade 55 bolts have a yield strength right around 55 ksi, which makes them pretty affordable option when constructing regular building frames. For situations where things get really heavy duty, Grade 105 bolts come into play these ones pack a 105 ksi yield strength and work well in places such as crane rail systems or big turbine bases. According to tests referenced in ASCE 7-22 standards, Grade 105 bolts can handle nearly three times the amount of repeated stress before they start showing signs of fatigue. That kind of durability is why engineers specify these bolts for projects facing tough conditions day after day.

Specialized Designs for High-Load and Dynamic Environments

In high-stress settings such as wind farms or seismic zones, anchor systems often incorporate double-nut configurations and vibration-dampening sleeves to mitigate material fatigue from lateral forces. Seismic-rated anchors maintain 98% of their load capacity after over 50,000 stress cycles (NEHRP 2020), demonstrating exceptional durability under dynamic conditions.

Assessing Load Requirements for Optimal Anchor Bolt Performance

Tensile, Shear, and Combined Load Types in Construction Applications

Anchor bolts deal with three main types of force: tension when something pulls straight out, shear when there's sideways movement, and combinations of these forces. Recent studies back in 2023 showed around 43 percent of all structural problems actually came down to not enough strength against tension forces. This happens quite often with things like hanging platforms or those big roof supports. When it comes to earthquakes, shear forces become king in how buildings brace themselves. And then there are situations where multiple forces work together at once, like highway signs dealing with both wind pushing them and gravity trying to pull them down. These cases need really careful math work from engineers to get right.

Static vs. Dynamic Load Considerations in Anchor Bolt Design

Static loads, like permanent structural weight, allow straightforward material selection. Dynamic loads from machinery or traffic necessitate fatigue-resistant materials. According to the 2025 Industry Report on Structural Fasteners, epoxy-coated bolts in dynamic environments last 30% longer than zinc-plated versions due to reduced micro-crack formation.

Impact of Vibration and Cyclic Loading on Material Fatigue

Cyclic stress leads to bolt degradation through:

- Progressive thread deformation (common in HVAC systems)

- Crack initiation at stress concentration points

- Fretting corrosion in unlubricated joints

A 2024 study revealed that J-bolts fail 19% faster than L-bolts under repeated loading due to uneven stress distribution.

Case Study: Failure Due to Underestimated Tensile Loads

A 2022 warehouse collapse was traced to undersized anchor bolts that supported only 65% of the actual tensile load from rooftop solar arrays. The investigation highlighted critical design flaws:

| Design Parameter | Calculated Value | Actual Requirement |

|---|---|---|

| Tensile Load | 12,500 lbs | 19,200 lbs |

| Safety Factor | 1.8 | 1.2 (post-failure) |

| Bolt Grade | ASTM F1554 Gr 55 | Required Gr 105 |

This incident led to updated ASTM guidelines (2023) mandating a 25% increase in safety margins for renewable energy installations.

Concrete Compatibility and Installation Engineering Criteria

Matching Anchor Bolts to Concrete Type and Compressive Strength

Choosing the right anchors depends heavily on what kind of concrete we're dealing with, both in terms of its compressive strength and how it was mixed. For regular concrete that ranges from 3,000 to 4,000 psi, L-bolts and headed studs work just fine most of the time. But when working with high strength concrete above 5,000 psi, things get trickier. We need those hardened steel fasteners otherwise there's a real risk of them pulling out under stress. Recent research from 2023 showed something pretty alarming too – nearly one in five structural failures happened because someone used the wrong combination of anchor and concrete type. That's why following ACI 318-19 guidelines about how deep to embed anchors according to the concrete grade isn't just good practice, it's essential safety protocol for anyone involved in construction projects.

Embedment Depth and Hole Diameter for Effective Load Transfer

Getting the right embedment depth is pretty important for bolts - generally somewhere between 8 and 12 times the actual bolt diameter works best for transferring loads properly. When drill holes get too big, like exceeding the bolt size by more than 1/8 inch, that can really cut down on how well the anchor holds everything together. Tests following EN 12504-1 standards have shown this actually reduces anchoring power by around 40%. With post-installed anchors in standard 4,000 psi concrete, sticking to a depth to diameter ratio of about 4 to 1 helps prevent cracks from forming while still keeping most of the original strength intact. This approach maintains over 90% of what was designed into the system in the first place.

Spacing and Edge Distance to Prevent Concrete Breakout

When dealing with shear forces, keeping edge distances between 5 and 7 times the bolt diameter helps prevent those annoying lateral spalling issues. The latest version of the Australian standard AS 3600 now specifies something interesting for thinner structural members less than 12 inches thick. According to these guidelines, anchors need to sit at least 1.5 times deeper than their embedment depth from edges. This simple adjustment has actually cut down on breakout problems by around 27% across various coastal construction projects. And don't forget about clustered anchors either. Make sure there's at least 10 bolt diameters between them so their stress areas don't overlap and cause unwanted complications during installation or operation.

Environmental Durability and Corrosion Protection Strategies

Weather and climate impact on anchor bolt longevity

Coastal installations experience triple the corrosion rate of inland sites due to saltwater aerosol exposure (Corrosion Science 2026). Temperature fluctuations exceeding 40°C accelerate galvanic corrosion, particularly in zinc-coated bolts subjected to freeze-thaw cycles.

Corrosion resistance in coastal and humid environments

Hot-dip galvanized (HDG) coatings outperform electroplated zinc by 85% in 300-day salt mist tests (ASTM B117), making HDG ideal for marine environments. In high-humidity industrial settings, epoxy-polyamide hybrid coatings exhibit 92% less pitting than standard galvanization (ISO 12944-9).

Galvanized, zinc, and HDG coatings: Effectiveness and cost comparison

| Coating Type | Salt Spray Resistance (Hours) | Cost (vs HDG) | Recoating Interval |

|---|---|---|---|

| HDG | 3,200 | 1.0x | 15-20 years |

| Electro-Zinc | 900 | 0.7x | 5-8 years |

| Epoxy-Zinc | 5,500 | 2.3x | 25+ years |

Long-term maintenance and coating degradation implications

In ISO C5 corrosivity zones, bolt coatings lose 18–22% of protective thickness within five years. Semi-annual inspections using ultrasonic gauges enable early detection of degradation, allowing timely recoating before structural integrity is compromised.

Application-Specific Selection Across Construction Use Cases

Anchor bolt applications in foundations, steel framing, and machinery anchoring

Critical projects demand tailored anchor solutions:

- Foundations: Cast-in-place anchors transfer vertical and lateral loads, with 89% of concrete foundations now requiring seismic-rated designs (NIST 2019)

- Steel framing: Coastal builds increasingly use hot-dip galvanized J-bolts compliant with ASTM A153 to resist saltwater corrosion

- Machinery anchoring: Industrial studies show F1554 Grade 105 bolts extend service life by 40% in high-vibration environments

Selecting anchor bolts based on project-specific loads and environment

Engineers prioritize tensile strength in seismic regions and shear resistance for crane rail systems. Coastal projects require zinc-rich coatings for 50+ year durability, while chemical plants use 316 stainless steel to withstand acidic exposure.

Rising trend of engineered fastening systems in industrial construction

Prefabricated anchor clusters with integrated load-monitoring sensors support 35% greater dynamic loads than conventional systems (ASCE 2023 benchmarks). These advanced assemblies also cut installation time by 60% in complex steel-truss projects.

Standardization challenges in regional building codes and regulations

The 2024 IBC update mandates 20% higher safety factors for anchor bolts in hurricane-prone areas—a requirement not mirrored in EU EN 1992-4 standards. This divergence compels global contractors to maintain dual inventory systems, increasing project costs by 12–18%.

FAQ

What are the common types of anchor bolts and their uses?

L-bolts, J-bolts, and headed studs are the common types of anchor bolts. L-bolts are typically used in concrete foundations; J-bolts are preferred for softer materials due to their curved shape, and headed studs are suitable for steel structures meeting concrete bases.

What is the difference between cast-in-place and post-installed anchor bolts?

Cast-in-place anchor bolts are set during concrete pouring, ideal for critical applications like seismic bracing. Post-installed anchors are added after pouring and are used for retrofitting. They require precise hole dimensions.

How do F1554 Grade 55 and Grade 105 bolts differ?

F1554 Grade 55 bolts have a yield strength of 55 ksi, suitable for regular construction. Grade 105 bolts have a higher yield strength of 105 ksi, making them ideal for heavy-duty applications like crane rail systems.

How does the environment impact anchor bolt performance?

Environmental factors such as weather and climate significantly impact anchor bolt longevity. Coastal installations are more prone to corrosion, which requires more resistant coatings like hot-dip galvanized (HDG) treatments.

What are some strategies for enhancing anchor bolt durability?

Using corrosion-resistant coatings, ensuring proper embedment depths, and selecting bolts according to specific load requirements and environmental conditions can enhance anchor bolt durability and performance.

Table of Contents

- Understanding Anchor Bolt Types and Structural Applications

- Assessing Load Requirements for Optimal Anchor Bolt Performance

- Concrete Compatibility and Installation Engineering Criteria

- Environmental Durability and Corrosion Protection Strategies

- Application-Specific Selection Across Construction Use Cases