Understanding Fasteners OEM and Customization Needs

What Are Fasteners OEM Services?

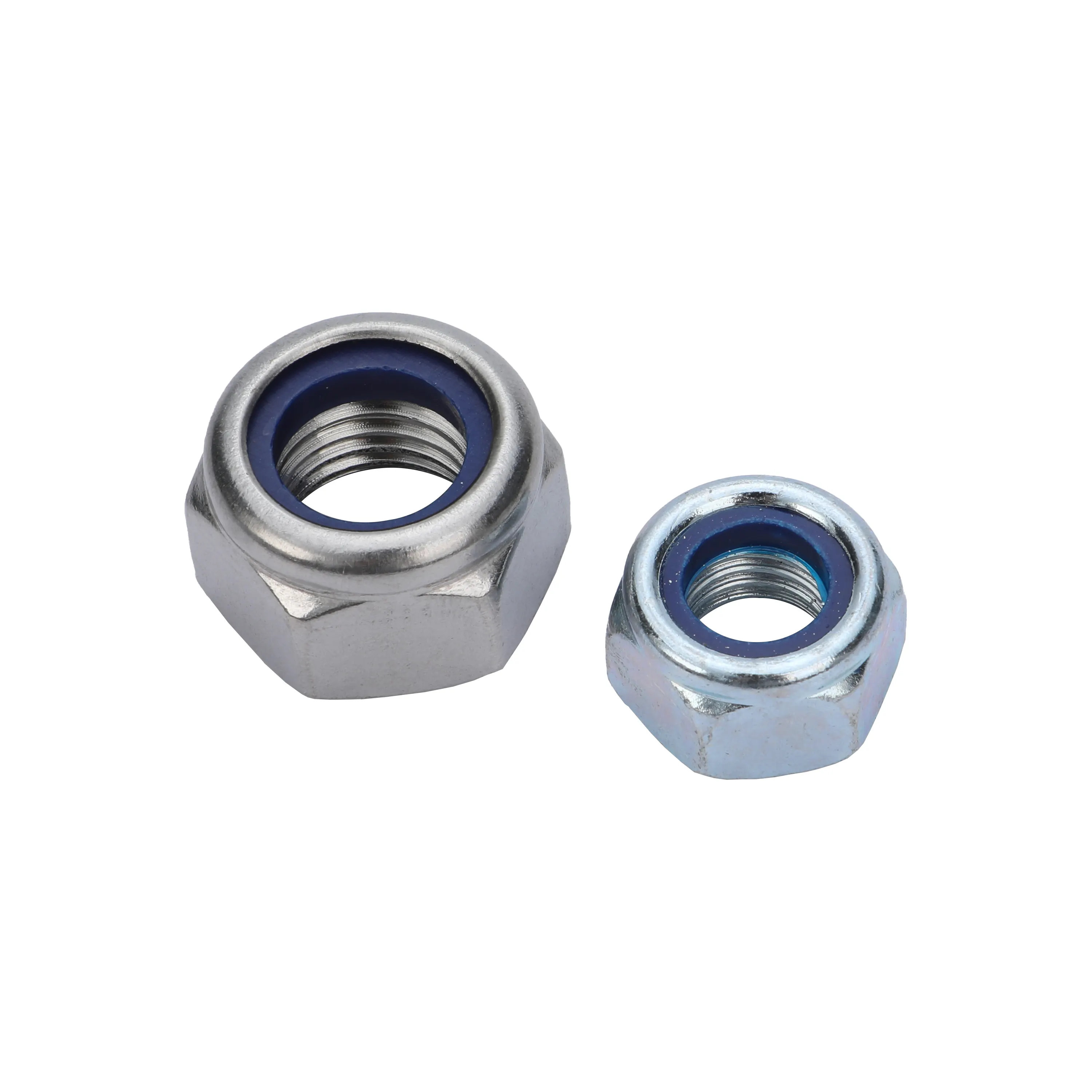

When it comes to fastener OEM services, we're talking about creating custom mechanical parts that fit exactly what specific equipment needs. Standard bolts and nuts just won't cut it here. These specialized solutions tackle those tricky requirements like size, materials, or how they perform under stress. Take automotive engines for instance. Sometimes they need special threading that can handle really high torque forces or squeeze into tight spots where regular hardware wouldn't work. The whole process usually starts with working closely together on designs, then making prototypes before full scale production kicks in. Everything gets made according to the exact specifications provided by original equipment manufacturers, down to every last detail in their blueprints.

Why OEMs Require Custom-Designed Fasteners for Specific Applications

Standard fasteners just don't cut it when things really matter, because small mismatches can actually bring whole systems crashing down. Take aircraft construction as an obvious case point these fasteners need tolerances so tight they're almost obsessive about dealing with both scorching heat and constant shaking during flight. Wind turbines tell another story entirely here manufacturers slap on special protective layers specifically designed to fight off rust after years battling rain, salt air, and whatever else Mother Nature throws at them. These specially made bolts and screws aren't just fancy they make all the difference between safe operation and catastrophic failure across industries where there's no room for error whatsoever.

The Role of Engineering Design in Custom Fastener Development

When developing fasteners, engineering crews typically turn to CAD tools along with finite element analysis (FEA) to tweak things like shape, materials used, and how surfaces are treated. Take marine environments for instance where engineers often pair stainless steel bases with zinc-nickel coatings because they stand up better against saltwater corrosion over time. The design team frequently collaborates with original equipment manufacturers too, trying to find that sweet spot between what works well and what stays within budget constraints. They keep standard features such as thread angles intact but will modify head shapes or choose different drive systems based on application needs. All these back-and-forth adjustments help create products that actually perform as intended while still being practical to manufacture at scale.

Engineering Design and Technical Specifications for Custom Fasteners

Blueprint Specifications: Dimensions, Materials, and Coatings

When making custom fasteners, engineers need pretty specific blueprints that include things like diameter measurements, thread pitch specifications, overall length requirements, and what kind of weight they can actually hold. For parts used in tough conditions, special coatings matter a lot. Zinc-nickel plating or those epoxy resin treatments really stand out compared to regular finishes. Some tests showed these coatings can cut down corrosion problems by around 70 percent according to the Material Performance Report from last year. The whole design process has gotten faster too thanks to digital CAD modeling. Automotive companies and aerospace manufacturers report saving anywhere between 30 to almost 45 days when moving from initial designs to actual prototypes now.

Engineering Drawing Requirements and Tolerance Control

When companies follow ISO 2768 or ASME Y14.5 guidelines, they generally get parts that fit together within about ±0.005 mm for those really important components. According to recent industry research from last year, around 8 out of 10 original equipment manufacturer engineers say clear GD&T specifications matter most when trying to prevent having to fix things after production starts. Some suppliers have started incorporating artificial intelligence tools into their CAD workflows, and these folks are seeing roughly a third fewer problems during prototype testing. This makes a big difference particularly in equipment subjected to constant vibrations, think wind turbine components where even small misalignments can cause major issues over time.

Material Selection and Optimization Based on Application Demands

Stainless steel Grade 316 is preferred for marine environments, while titanium alloys serve weight-sensitive aerospace roles. Heat-treated alloy steel has been shown to increase fatigue life by 200% in off-road vehicle suspensions. Engineers use FEA simulations to balance tensile strength (₰¥1,200 MPa) with cost-efficiency, ensuring optimal material selection for each application.

Standardization vs. Full Customization: Balancing Flexibility and Efficiency

Using hybrid methods where companies modify existing ANSI or DIN designs instead of creating everything from scratch can cut down on tooling expenses by about 60%. Take for instance when someone adds their own special thread pattern to a regular M12 bolt. This simple modification works great for specific needs in hydraulic systems without having to completely redesign the whole fastener component. According to industry reports, roughly two thirds of manufacturers actually go this route because it helps them keep things scalable while working with original equipment manufacturers (OEMs). Makes sense really since nobody wants to spend extra money on full customization when there are good alternatives available.

Custom Fastener Manufacturing: From Prototyping to Built-to-Spec Production

Overview of the Custom Fastener Manufacturing Process

Manufacturing typically starts off with going over the design specs to check if the threads are right, what kind of materials will work best, and whether it can handle the expected loads. Components get shaped through CNC machining and forging techniques that can hit really tight tolerances sometimes down to around 0.01 mm either way. After the main shaping is done, there are several finishing touches like heat treatments which make things stronger, plus coatings such as zinc-nickel plating that help protect against rust and wear. When it comes to quality checks, manufacturers run tests on coordinate measuring machines (CMM) and do salt spray tests too. All these steps need to meet those ISO 898-1 standards for fasteners, so most shops have pretty strict protocols in place for every batch they produce.

Built-to-Spec Production for Complex OEM Requirements

In demanding sectors like aerospace and renewable energy, built-to-spec production delivers fasteners capable of enduring extreme temperatures, vibrations, or chemical exposure. Key capabilities include:

- Material optimization (e.g., titanium alloys for superior strength-to-weight ratios)

- Custom coatings such as Xylan® for friction reduction

- Geometric adaptations for tight installation spaces

This approach reduces assembly errors by 27% in high-precision equipment (ASM International, 2024) and supports certifications like AS9100 and NADCAP.

Short-Run Production for Prototyping and Testing

Short-run batches of 50â€"500 units allow OEMs to test fastener performance under real-world conditions before scaling up. Prototypes undergo:

- Functional Testing: Load capacity, fatigue resistance, and thread engagement

- Environmental Simulation: Salt fog exposure for 500+ hours to evaluate coating durability

- Compatibility Checks: Interaction with mating parts during thermal cycling

This phase identifies 92% of design flaws (ASTM International, 2023), enabling cost-effective refinements prior to full production.

Surface Treatments and Coatings for Enhanced Fastener Performance

Advanced Coatings for Corrosion Resistance and Durability

Coatings engineered specifically for fasteners can really boost how long they last before needing replacement, mainly because they shield against chemicals, regular wear and tear, plus those brutal temperature swings. Zinc plating works okay for everyday conditions, but when things get serious like in boats or planes, folks turn to cadmium and chromium plating instead. These materials stand up better to saltwater corrosion and won't break down under UV light exposure. For wind turbines and solar panels where electricity matters a lot, epoxy resin coatings keep everything insulated properly. And don't forget about MoS2 coating on hydraulic parts either it cuts down friction so much that even under extreme pressure, these components run smoother without overheating as quickly.

Tailoring Surface Treatments to Environmental and Functional Conditions

Getting good results means finding coatings that actually stand up to what they face day to day. Take PTFE coatings for instance these are commonly applied on fasteners inside chemical processing facilities where they shield against those pesky acidic fumes. Over in agriculture, equipment manufacturers often turn to sacrificial zinc nickel alloys because regular steel just doesn't cut it when machines are constantly battling gritty soil conditions. Now there's this new wave of nanocoatings coming through the market too. These super thin layers can actually repair themselves when damaged, which is pretty handy for HVAC systems dealing with all sorts of humidity fluctuations throughout the seasons. For original equipment manufacturers working across different sectors, these advanced materials help strike that tricky balance between durability, keeping things lightweight, and staying within budget constraints.

Selecting the Right Fasteners OEM Partner: Collaboration, Expertise, and Value

Key Criteria for Evaluating Fasteners OEM Services and Suppliers

Finding the correct manufacturing partner means looking at several key factors. Production capacity is essential for most businesses, especially those needing to produce over 30,000 units per month. Quality standards matter too, with around 92% of leading suppliers meeting ISO 9001 requirements these days. Material knowledge and how quickly a supplier can respond during prototype development rounds are equally important considerations. Recent industry research shows that nearly seven out of ten engineers prefer working with manufacturers who can build products to specific customer specifications rather than relying on standard off-the-shelf options. Experience across different sectors tends to make a real difference, particularly when dealing with aerospace or automotive components where precision counts. Suppliers with cross-industry backgrounds typically achieve much tighter tolerances around ±0.005 mm compared to the average ±0.02 mm seen among general industrial providers.

The Importance of Technical Support and Innovation in Customization

Getting good results from OEM partnerships really hinges on working together technically. According to research from the Ponemon Institute last year, companies that offer specific material advice for applications saw their prototype failures drop by about 41% when compared to regular vendors who just sell products. Top tier collaborators use simulation software to figure out how loads are distributed and model corrosion risks. This matters a lot in tough spots like offshore oil rigs or places where chemicals are processed regularly. The right simulations can make all the difference in these demanding conditions.

Cost vs. Lifecycle Value: Strategic Benefits of OEM Fastener Customization

Custom fasteners do come with a price tag about 15 to 30 percent higher than what we see with standard parts, but looking at the bigger picture shows they're worth every penny. Maintenance doesn't need doing as often either—think 3 to 5 years between checks instead of just 18 to 24 months—and replacements happen far less frequently too. When put through ISO 9227 salt spray tests, these specially coated fasteners used in those high voltage boxes actually held up against corrosion 89% better after a decade than regular zinc plated ones. So when manufacturers invest money upfront for custom solutions, they're really getting something that lasts longer and works better, making it smart business sense rather than simply another expense on the books.